So, last week before Christmas (also late merry Christmas)

I was running this super neat and terrifying Hydraulic press.

I asked are resident machinist about it, and he told me “it was a military surplus Hydraulic press, it was originally made for WW2 and crimped bullet casings”.

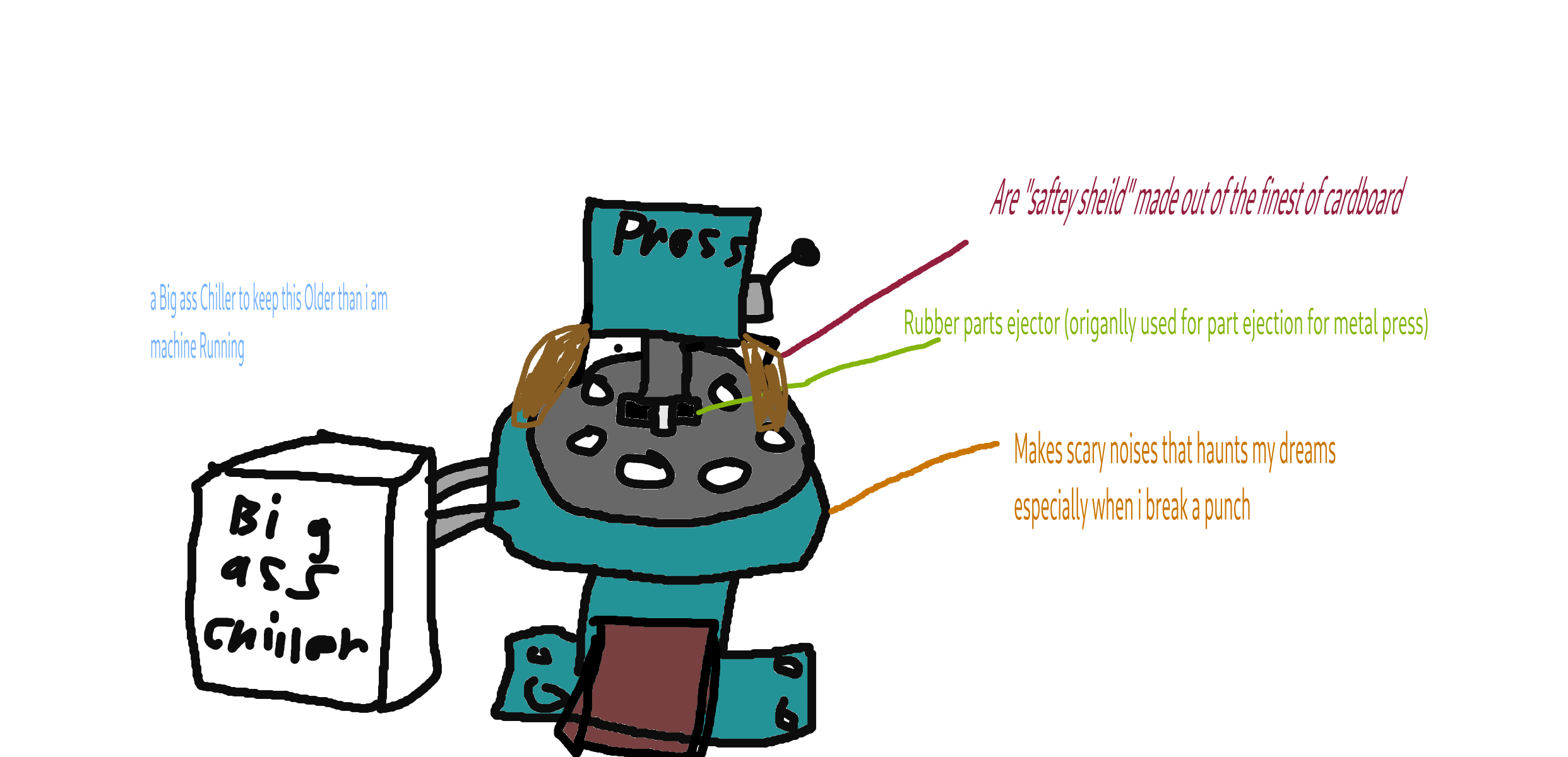

I can’t show a photo of it because it’s in are store room with lots of “trade secret” stuff. But ill explain it with a very poorly drawn version

It was really neat to learn about the history of this neat machine. And the challenges we’re currently dealing with. Such as it runs for 20 mins then shuts off the one smart other maintenance guy said it was the pump going bad and we’re probably going to have to replace it. The press is kinda scary though, the punches blow apart if you load something wrong (which is my fault) and hearing it start to move down the punch is quite scary as I have seen punches explode, and metal shards fly everywhere. But it was kinda fun in the scary kinda way!

We have a bunch of these Denison presses in various sizes at my job; used mostly for clipping and bending. They do damn good work, but any parts that can’t be sourced from McMaster are getting near impossible to find. Anything we can’t make in house normally gets pulled from spares in the warehouse, and we’ve since moved towards building our own presses. It’s a shame, since the cast iron on these will last forever.

Also, we had one acting similarly a couple years back. We thought it was a smoked pump, but it wound up being a sticky solenoid. It’d be in that gray box on the top right in your photo. Wound up being a pretty simple fix.

In the new year will you be moving on to more pressing matters?